Li-ion or Lead-Acid Battery – Which one is better? If your back-end operations involve multiple shifts, switching to Lithium-ion battery makes a lot of sense.

If you are in a quandary whether to replace your Lead-Acid Forklift battery with a Lithium-Ion battery, you have come to the right place. For the uninitiated, there are two types of electric forklifts in the market today. Those powered by Lead-Acid Batteries (also known as LAB) and those powered by Lithium Ion Batteries (also known as LIB).

Compared to a Lithium-ion battery, the Lead-Acid batteries are much cheaper and pose lower initial costs (low Capex) to the end user. However, the Lead-Acid batteries require a lot of maintenance and come with their own demerits as compared to Li-ion batteries which are maintenance free. Companies around the world have begun to realize the long term advantages of the Lithium-ion batteries.

So is a Lithium-ion battery really a game changer? Is it economical in the long run? What advantages do they have? There could be many such questions that could be lingering in your mind if you are a decision maker.

So, if you are thinking about switching over to Lithium batteries, but not sure if it is right for your business, we list out 10 factors of ownership to be considered w.r.t. lead-acid batteries and Lithium-ion batteries that would help you make the right decision.

- Initial cost – On an average, The Lead-Acid batteries are nearly 3-4 times cheaper compared to Lithium-ion batteries. With such a low cost of procurement, you would think that a Lead Acid Battery should be the battery of choice for forklift right? Well, it depends on various factors, with operational load being a prime factor. There are many other factors apart from low initial cost to be considered for deciding which battery is right for you. Low purchase cost does not equate to low cost of ownership. To understand what other factors play a major role, read further.

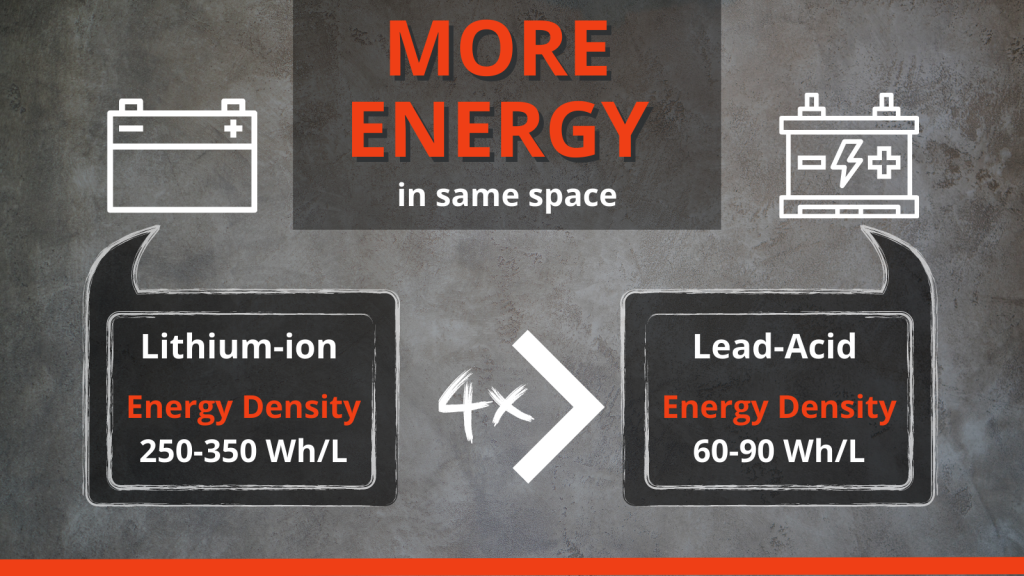

- Manpower Cost: Lead Acid batteries have lower power density as compared to a lithium ion battery. A Li-ion battery packs much more power within the same space. Because of this, the lead-acid battery requires swapping batteries twice in a shift, leading to non-productive labour time of about 15 minutes per swap. For operations with multiple shifts, that equates to 75-90 minutes of unproductive labour per day.

- Maintenance Cost: The Lead-acid batteries require high maintenance. Watering a battery can be tricky. Not only overwatering or underwatering a battery can result in deterioration in battery life, it also requires extensive use of Personal Protective Equipment (PPE) by the maintenance personnel to guard against harmful battery fumes. The labour cost toward maintenance and for procuring PPE are both added costs and it might not be much if you are running a small facility, but it significantly adds up when there are many material handling units in a facility.

- Cost of Spare Battery: With a lead acid battery, you require to keep more batteries in stock to swap during the downtime, as lead-acid batteries cannot power the whole duration of the shift. In contrast, the Lithium-ion batteries store 4 times more energy than a Lead-Acid battery. While lead acid batteries can only achieve an energy density of 60-90 Wh/L, a lithium-ion battery can pack energy density in the range of 250-350 Wh/L. Typically, for every 3 lead acid batteries, you need 1 Lithium-ion battery.

- Storage space: With a Lead Acid Battery, you require dedicated space for storing the discharged batteries and carrying out routine maintenance. This is not required for a Lithium-ion battery as they can be charged easily and do not require dismounting. Hence the space saved can be used for other productive operations.

- Cost of Utility: The lead acid batteries are less energy efficient and consume more electricity to charge to the same levels. Lead Acid Batteries consume 30-50% more power than Lithium Ion Batteries. On an average, 15% of the operating budget for a facility is spent on utility bills. A reduction in utility bill directly results in more profits. Further

- Cost of Replacement: Lead-acid batteries have a cycle life of only 1500-2500 cycles depending upon how it has been maintained. For a facility having single shifts and lesser requirements of forklifts on day-to-day basis, the lead-acid batteries can last for years. But for a multi-shift facility, it means that the batteries have to be replaced faster. This adds to the cost of replacement as well. On the other hand, Lithium-ion batteries have a phenomenal cycle life and last 4-5 times longer.

- Performance Degradation: Forklift performance with Lead Acid batteries drops as the charge level goes down below 50%. Compare this with a Lithium Ion Battery, where the battery powers the vehicle uniformly irrespective of its state of charge. This has a great impact on productivity. Imagine being on a critical task just as your forklift begins to power down. The psychological aspect of that itself would make the operator not take any risk when the battery level goes below a threshold, and proceed to change the battery. It’s just a drain on precious time.

- Health and Safety: Since the Lead Acid batteries have to be changed twice per shift, it opens up the possibility of safety hazard during battery swapping. Further, the fumes from lead acid batteries pose health hazards for the personnel during maintenance, not to mention the fume build-up in closed spaces of a distribution center. On the other hand, Lithium-ion batteries are maintenance free and do not require to be swapped to keep the forklift working.

- Longer Charging times: A Lead Acid Battery requires longer charge times of 8-9 hours to fully charge compared to a Lithium ion battery that can be fully charged in less than an hour. Further, Lithium-ion batteries can be opportunity charged i.e. they can be recharged during breaks throughout the day. It is as simple as plug and play.

So what applications are most suitable for Lithium-ion forklift batteries?

Today, if you run any facility that has multi-shift requirements – such as a cold storage facility or a large distribution center or any facility dealing with material handling, where operations continue 24X7, you need Lithium-ion batteries. Lithium-ion batteries would not only prove to be better return on investment in the long run, it would also make the operations more efficient.

Raymond – a leading material handling electric vehicle manufacturer has published a cost savings calculator (Check here). As per Raymond, a big facility would realize the return on investment on a Lithium-ion battery within months, and provide substantial savings in the long run.

Electrovaya’s Lithium-ion Ceramic battery solutions

A large number of our clients who are Fortune 100 companies have done the math and realized that having a Lithium-ion forklift battery reduces their operational cost, increases productivity and helps eliminate down time because of its ease of use.

You can find here some of the businesses that have benefited from our battery solutions. Electrovaya’s battery technology provides proven cost saving by providing industry leading cycle life, high safety and high reliability. Click here to find out more about how our solutions can make a difference to your business.