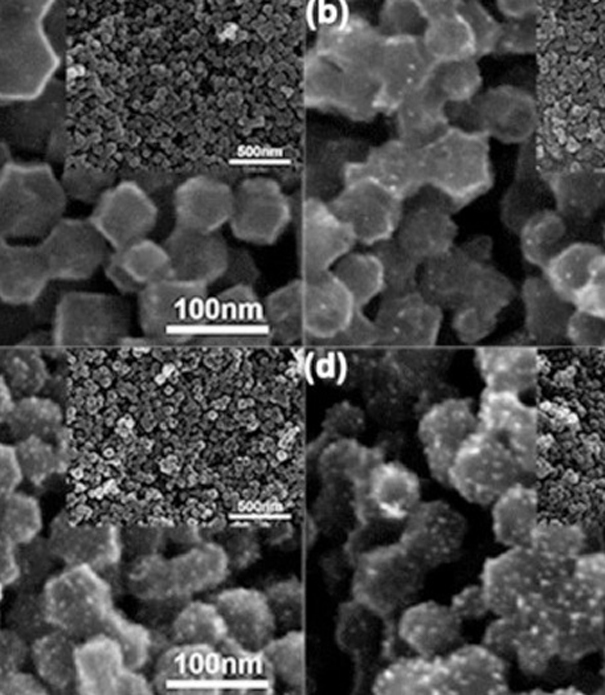

Significant Patent Holdings for Ceramic Separator Technology

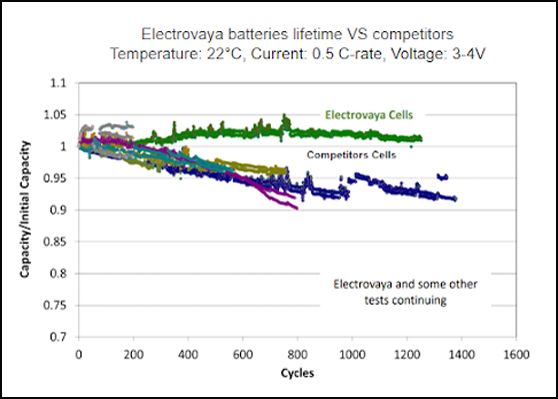

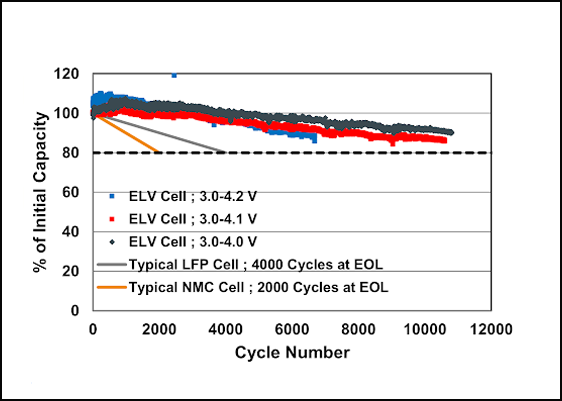

We call them 'multi-million-mile batteries' as they have the best cycle life in industry and give the lowest cost of ownership compared to other Lithium-ion batteries, fuel cells and lead acid batteries

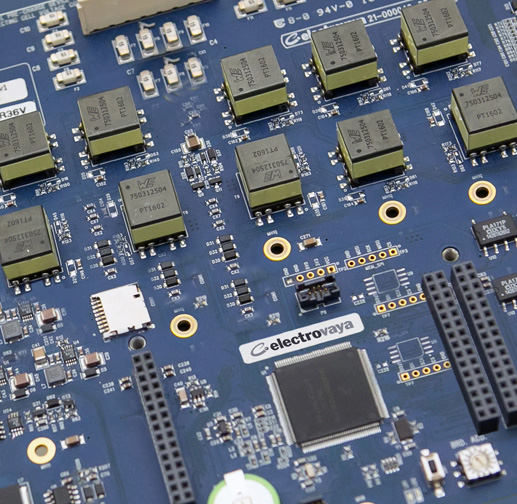

5th generation Battery Management System (BMS) developed in-house

Electrovaya announces breakthrough performance for proprietary solid-state hybrid battery technology

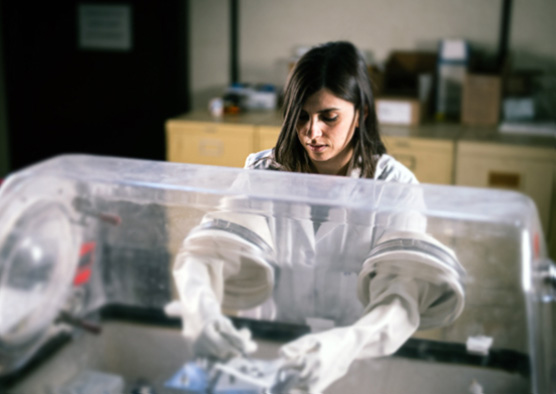

Proprietary approach to solid-state batteries featuring innovative technology, and responsible manufacturing process

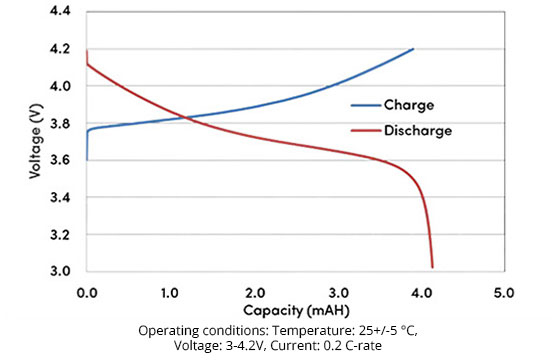

Achieving Industry leading energy density with Lithium-metal anode, high performance NMC cathode and proprietary solid composite electrolyte

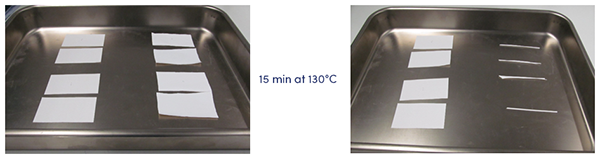

Designed for mass production - Uses commercially mature technology and sustainable cost-effective manufacturing process

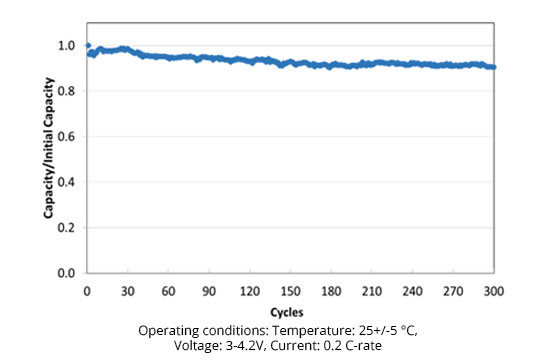

Promising preliminary room temperature cycle life results using Lithium-metal anode, NMC cathode and proprietary solid-state electrolyte. Highlights the ability of the technology to meet passenger automotive applications, which target 800 cycles with 80% capacity retention

Operating conditions: Temperature: 25+/-5 °C, Voltage: 3-4.2V, Current: 0.2 C-rate

Cloud-based battery analytics system for remote monitoring of the batteries

Non-Toxic electrode coating process with lower Capex and Opex