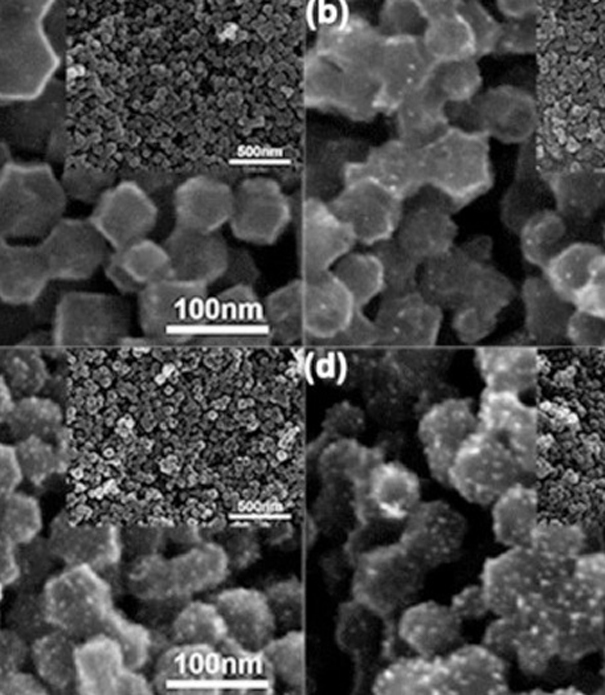

Significant Patent Holdings for Ceramic Separator Technology

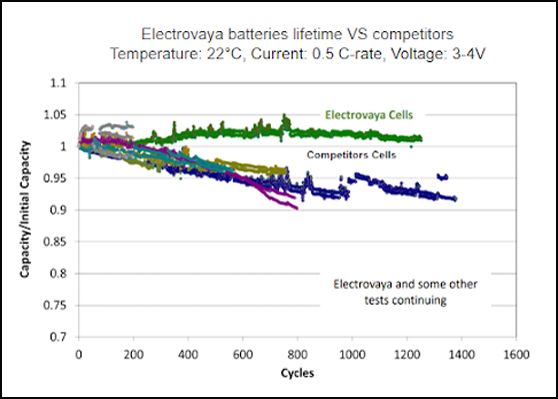

We call them 'multi-million-mile batteries' as they have the Best Cycle Life in Industry and give the lowest cost of ownership compared to other lithium ion batteries, fuel cells and lead acid batteries

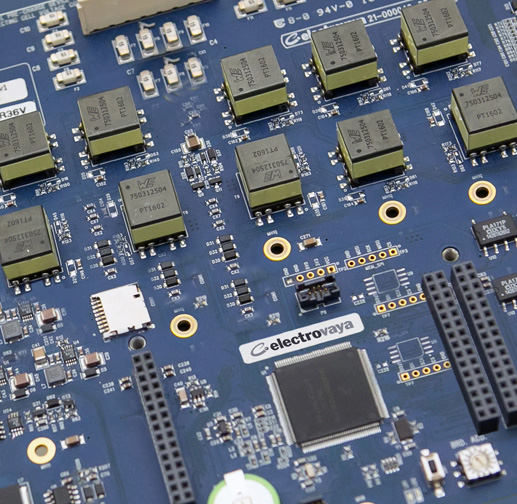

5th generation Battery Management System (BMS) developed in-house

Electrovaya Announces Breakthrough Performance for Proprietary Solid State Hybrid Battery Technology

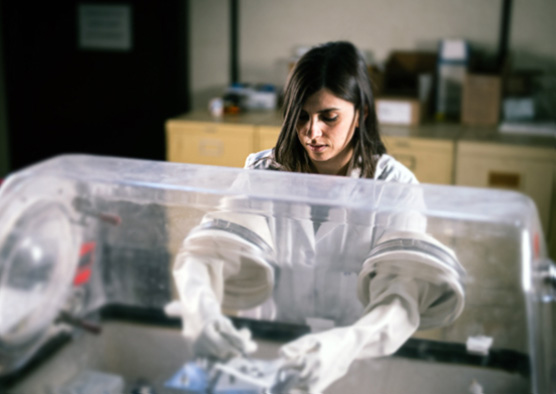

Proprietary approach to solid-state batteries featuring innovative technology, and responsible manufacturing process.

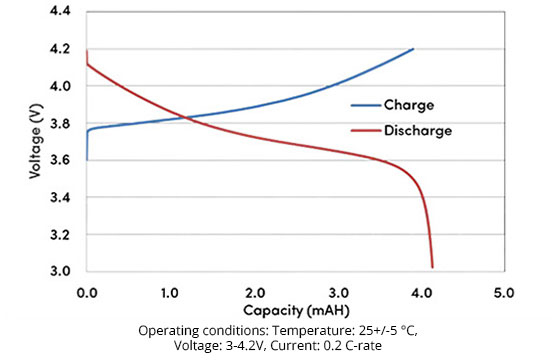

Achieving Industry leading energy density with Lithium metal anode, high performance NMC cathode and proprietary solid composite electrolyte.

Designed for mass production - Uses commercially mature technology and Sustainable cost-effective manufacturing process.

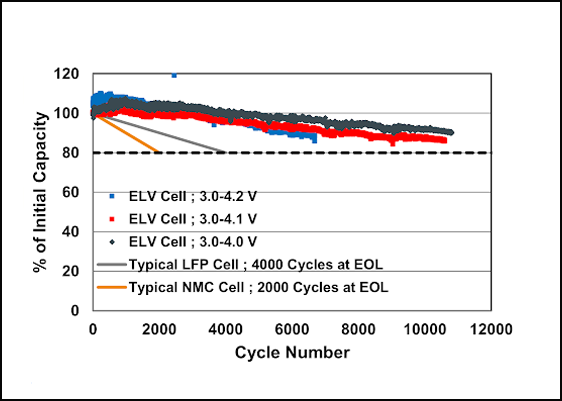

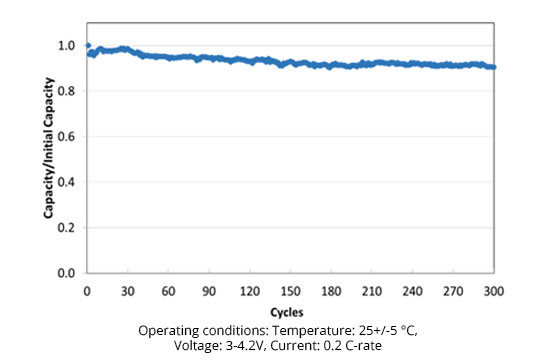

Promising preliminary room temperature cycle life results using Lithium metal anode, NMC cathode and proprietary solid-state electrolyte. Highlights the ability of the technology to meet passenger automotive applications, which target 800 cycles with 80% capacity retention.

Operating conditions: Temperature: 25+/-5 °C, Voltage: 3-4.2V, Current: 0.2 C-rate.

Cloud-based battery analytics system for remote monitoring of the batteries

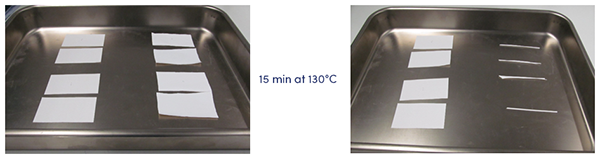

Non-Toxic electrode coating process with lower Capex and Opex